Details

SonoFlux Servo SonoFlux Servo Ultrasonic Spray Fluxer

![]() To see a video of this product, click here

To see a video of this product, click here

Fully Automated Ultrasonic Reciprocating Spray Fluxing System

The SonoFlux Servo is a fully automated ultrasonic spray fluxing system designed on a high accuracy reciprocating platform. The ultrasonic atomization module uses a high Impact flux transfer system for maximizing top-side fills. The system is designed for complete flexibility - making it ideal for contract manufacturers making frequent product changeovers. All process parameters are controlled with a user-friendly Windows-based interface. SonoFlux Servo is compatible with all fluxes, including those used in lead-free manufacturing..

The SonoFlux Servo system has many integrated features:

- 500,000 recipe storage

- Single or dual mode fluxing

- Easy integration and operation with all wave solder machines

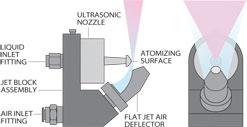

- Non-clogging ultrasonic atomizing nozzle

- High precision flux delivery pump

- Conveyor speed sensing option

- Low maintenance design reciprocator

- Uniform coverage

- Reduction in flux consumption up to 80%

Impact Ultrasonic Nozzle

The SonoFlux Servo system can either be installed internally in your wave solder machine or is available as a stand-alone unit.

The system is also equipped with a high Impact flux transfer system to help with PCBs that have difficulty with top-side fill, such as those with thick back planes, tight lead-to-hole ratios, or ontaminated components.

Industry Proven - Sono-Tek spray fluxing systems with an non-clogging ultrasonic nozzle and spray dispensing mechanism have been proven in thousands of industrial PCB fluxing applications worldwide.

Flux Application - Flux is supplied from a closed reservoir by a positive displacement gear pump. The unpressurized flux reservoir includes a level sensor to alert the operator to a low level flux condition. The flux is atomized into a fine mist at the tip of the non-clogging, large-orifice ultrasonic nozzle which is reciprocated below the PCB, directing flux upward.

FLEXIBILITY - SonoFlux Servo can store up to 500,000 recipes, can be run in single or dual mode, and has a conveyor speed sensing option, making it ideal for high mix contract manufacturing.

Fastest Payback - In many installations, Sono-Tek systems have a reduced flux consumption by up to 80% as well as reducing solder defects by a similar percentage. Compared to foam fluxing, additional savings are achieved by the elimination of thinner and titration checks, as well as reduced waste disposal costs. Sono-Tek systems have also been shown to reduce flux consumption by up to 50% when compared to conventional spray fluxers.

Service and Support - Sono-tek Corporation prides itself on offering technical support second to none. North American-based service personnel and international distributors with factory-trained technicians provide this high standard of service throughout the world.

Additional Information

| SKU | SFLUX-SERVO |

|---|---|

| Manufacturer | No |